Product description

Unlike powered engines, gas is fed without additives into the combustion chamber of gas-powered vehicles. The protective function of the additives contained in gasoline is absent which increases the stress on valves and valve seats.

Valve protection is especially important in gas-powered vehicles!

V-LUBE Valve Saver forms a protective film which minimizes the stress on the valves and valve seats. Additive particles are released during the combustion of V-LUBE Valve Saver and are transported to the valves and valve seats along with the exhaust gas flow.

The valve and valve seat surfaces are coated by the V-LUBE particles in the thermal environment of the exhaust gas flow (1400-2000°C). The wear and tear of valves and valve seats is thus reduced to a minimum. In fact the wear rate has been proven to be even lower than the common wear tolerances when compared with gasoline operation.

V-LUBE Valve Saver features an additional cleaning and lubricating agent component. This component allows V-LUBE Valve Saver to be added via the V-LUBE Electronic Valve Saver Kit directly into the gas line. Injectors and gas pipes are here cleaned from any residues and contamination (Not to be used with baffle injectors).

V-LUBE Valve Saver is compatible with all commercially available metering systems.

The additive is mixed in via a metering system (Lubrication Kit) at a ratio of 1:1000 (10ml in 10 liters of fuel).

Accordingly, one liter of V-LUBE Valve Saver protects the engine for ca. 6,000 miles (10,000 km), depending on the vehiclespecific fuel consumption.

Product details

Overview of all V-LUBE Valve Saver product benefits.

- Protects valves and valve seats against increased stress

- Cleans the nozzles and fuel lines

- Increases efficiency and life of the engine

- Provides optimum protection with proper dosage

- Compatible with all metering systems available on the market

- Approved for injector add-on (only tappet injectors) – The additive is metered into the fuel line of the gas system and distributed via the injectors

- Long Life Effect lasting effect of the additive even in case of metering outage (for up to 1,000 km)

- No adverse effects on the catalytic convertor

- Reduces the maintenance required of petrol-powered engines (simply added into the tank)

The V-LUBE Quality Promise

Approved quality

We subject V-LUBE Valve Saver regularly to independent quality tests performed by TÜV Nord to achieve sustainable quality assurance. Therefore, you can always rely on the highest quality protection for your engine.

Reliable protection

We supply responsible LPG/natural gas drivers with a reliable product: its effectiveness is proven by facts, not by advertising promises. The effectiveness and the reliable protection of V-LUBE Valve Saver have been confirmed by several independent efficacy and longterm studies with outstanding results.

Sustainability

We are the only manufacturer who have had the longterm effects of V-LUBE Valve Saver on the sensitive vehicle’s catalyst examined. We can confirm that the highgrade additives in V-LUBE Valve Saver do not affect the efficiency nor the service life of the catalytic converter.

“Valve protection is not enough!”

Transparency

All quality tests and efficacy studies are available for download online at http://www.v-lube.com/ and confirm the highlighted quality characteristics to the fullest extent.

Testing process

We have run several tests on V-LUBE Valve Saver since the product launched in 2009 to independently verify the product’s quality and effectiveness. The summary of these tests can be found in the next section.

Result: Putting V-LUBE Valve Saver through such stringent tests means we can guarantee our product claims and make sure your engine is receiving the best care.

Zusammenfassung aller Tests

Annual quality control (carried out by TÜV Nord)

TÜV Nord tests V-LUBE Valve Saver at regular intervals to ensure consistent quality. The quality tests have been carried out since the product was launched and ensure consistent product quality. In all the subsequent longterm and efficacy tests the same V-LUBE Valve Saver product has been used as is still sold today.

Reliable protection through repeatedly and independently confirmed effectiveness

Studies 1 and 2 focused on confirming the effectiveness of V-LUBE Valve Saver with out a metering system. In the long-term practice test (Study 3), the V-LUBE Valve Saver Kit was used to test the dosage of V-LUBE Valve Saver in real-life conditions.

Efficacy Study 1

Summary of study report on the effectiveness of the additive agent on the engine test bench. Conducted at the Saarland University of Applied Sciences.

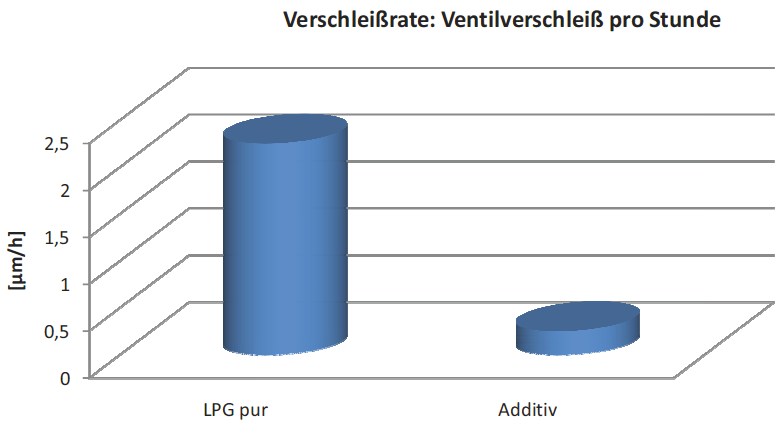

Procedure: Different engine operating points were set on the engine test bench and the wear and tear rates during operation without additive were checked. To test the effectiveness of the additive, the operating point which presented the highest wear was then repeated with LPG and additive.

Conclusion: No significant wear was detected after 20 hours that exceeded the margin of error. The wear protection seemed to take effect immediately and efficacy was confirmed with the dosage used. Furthermore, it is assumed that the protective layer built up by the additive will persist and continue to offer protection even for a period after the additive is no longer supplied. The length of time of this persistency was however not determined. In the study, a 2.0 liter Mazda engine was used. This engine is often used in various Ford models and is not deemed gas resistant.

Efficacy Study 2

Summary of valve wear examination driving test on a Peugeot 107 in LPG operation with added V-LUBE agent. Conducted at the Saarland University of Applied Sciences.

Procedure: A 6,250mile (10,000 km) field test of the fuel additive was carried out on a Peugeot 107 with a liquid phase LPG system. The vehicle featured a 3-cylinder Toyota engine, which is not gas resistant. The car was first driven without protective additives and the valve clearance was checked at a mileage of 7,800 miles (12,500 km).

To optimize the vehicle for LPG operation, the geometrical compression ratio was increased from 10.5:1 to 12:1. This modification should bring about an increased valve wear when compared to the reference value determined previously. The first check of the valve clearance at 3,650 miles (5,851 km) showed that the use of the additive had stopped the valve impact wear on the exhaust valves. Minimal discrepancies in the valve clearances in the range of 10 microns were present but were on average 0μm. The expected valve wear value for 3,650 miles (5,851 km) without additive would have been 33,9 microns given the observed reference values and would certainly have been detectable with the measuring instruments used.

In the second and final check of the valve clearance at 6,467 miles (10,408 km), a mean valve impact wear of -0.008 microns +/ 2 microns/625 miles (1,000 km) was measured over the entire test. This test therefore confirms the effective valve protection of V-LUBE Valve Saver.

Conclusion: We can say that no wear could be detected on any of the valves which would have reached the extent of additive-free operation.

Efficacy Study 3

Summary of the long-term road test on valve wear in LPG operation, wear considerations on a Toyota Corolla Verso and check of the V-LUBE Valve Saver Kit. Conducted at the Saarland University of Applied Sciences.

Procedure: An alternative fuel supply system was retrofitted on a Toyota Corolla enabling operation with LPG. An evaporator system with additive metering system manufactured by V-LUBE was installed.

The vehicle used a 1.8 liter VVT-i series gasoline engine. This engine is particularly suitable for this study because no specific valve train weaknesses are known in gasoline mode whereas LPG operation is known to cause valve impact wear.

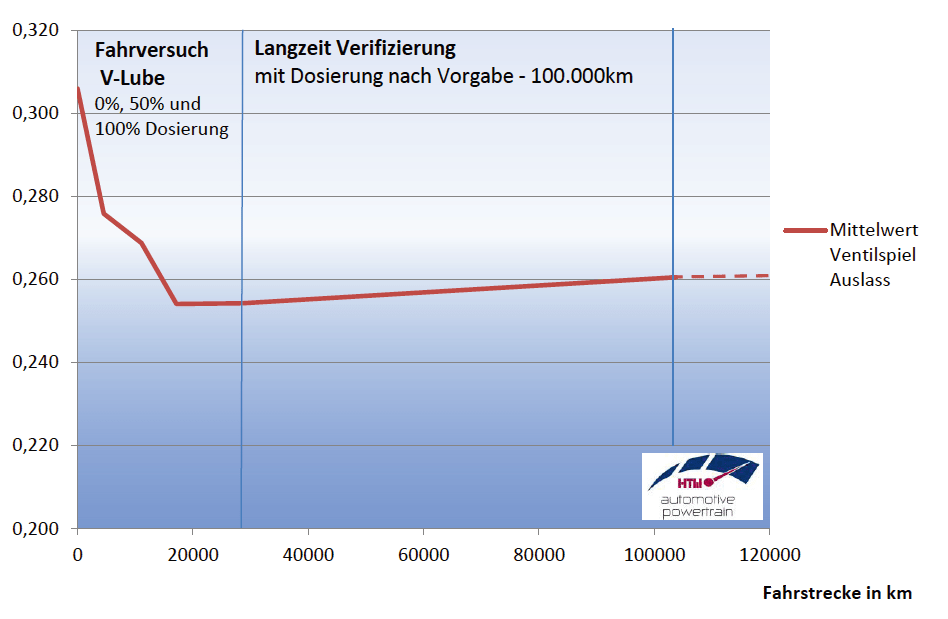

In order to evaluate the wear in LPG mode, the vehicle was driven for approximately 3,100 miles (5,000 km) in pure LPG mode and the change in the valve clearance was determined as an indicator of valve wear.

To evaluate the reduction in wear by the additive system, the vehicle drove 6,250 miles (10,000 km) with different settings. Again, the valve wear was determined via the change in the valve clearance.

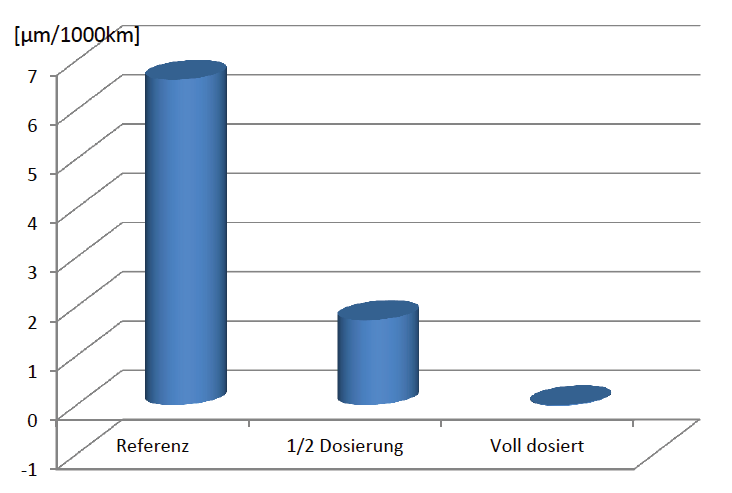

The graph below shows the valve lash progress at intake and exhaust valves. The first column indicates the wear during the additive-free reference measurement and the other two columns show the wear rate at the tested doses. In this case, the car drove 2,846 miles (4,554 km) for the reference measurement and the exhaust valves resulted in average wear of 30 microns. The calculated reference value is therefore 6.6 microns per 625 miles (1000 km). Up until trial mile 7,500 (1,2000 km) approximately half the metering rate recommended by the manufacturer was used, and after mile 7,500 (1,2000 km) the dosing was increased to the manufacturer’s recommendation.

If the wear rates on the exhaust valve resulting from the first two test phases are opposed to each other, the exhaust valves show a significant effect that corresponds to a wear reduction down by one third.

This corresponds roughly to a tripled service life of the valves.

Conclusion: Long-term efficacy verified after 78,750 miles (126,000 km) These findings show definitively that the use of V-LUBE Valve Saver significantly reduced the valve wear. If no additive had been used during LPG operation, the vehicle would likely have failed at mile 12,500 (20,000 km) of the test due to loss of compression.

As Figure 4 shows, no wear can be detected if the dosage recommended by the manufacturer is used although the vehicle is subject to wear even in gasoline mode. According to the vehicle manufacturer, the valve clearance must be checked every 37,500 miles (60,000 km).

Therefore it was proved if the valve protection is metered correctly, the service life of the valves is sufficiently prolonged so as to last over the full service life of the vehicle.

Study 4 Catalyst Test

Investigative report on the effects on the catalytic converter in a long-term test with V-LUBE Valve Saver. Conducted at the Automotive Powertrain Institute at Saarland Academy of Sciences.

Study 4 examined the long-term effects of V-LUBE Valve Saver on the catalytic converter. Recurring reports of wear to catalytic convertors due to the use of valve protection additives prompted us to have the long-term effects of V-LUBE Valve Saver examined, and the results were positive.

Procedure: The study was commissioned and conducted using a vehicle with a retrofitted LPG fuel system. LPG will typically cause increased stress on the gas exchange valves. The test vehicle was a Toyota Corolla Verso 1.8 VVT-i (94 kW/129 hp). During a long-term road test, it was operated with an additive that increases the service life of the valves (V-LUBE Valve Saver) using LPG as a fuel. A significant reduction in wear could be demonstrated at this point.

The functioning of the catalytic converter was checked, in order to assess any adverse effects of the additive on its service life.

Examination data, the vehicle had reached a mileage of 92,500 miles (148,000 km), of which it had been run over 78,750 miles (126,000 km) with LPG and the valve protection additive V-LUBE Valve Saver.

Conclusion: The measurement results of the catalytic converter examination prove that the long-distance use of the additive V-LUBE Valve Saver over 78,750 miles (126,000 km) does not adversely affect the function of the catalytic converter.

The determined conversion ratios are positive and show that the catalytic converter of the test vehicle is still functional even after a long-term endurance test with the additive V-LUBE Valve Saver.

This study did not reveal any malfunction of the catalytic converter. Thus, no negative effects by the use of antiwear additive V-LUBE Valve Saver on the exhaust after treatment system could be determined despite the considerable mileage of the test vehicle.

We look forward to hearing from you

Do you have any questions or suggestions?

Please contact us. We will be happy to help you.

Please contact us. We will be happy to help you.

![Figure 2: Average value (valve wear [μm/1000km]) Figure 2: Average value (valve wear [μm/1000km])](https://hybridsupply.uk/wp-content/uploads/Abbildung-2.png)