Product description

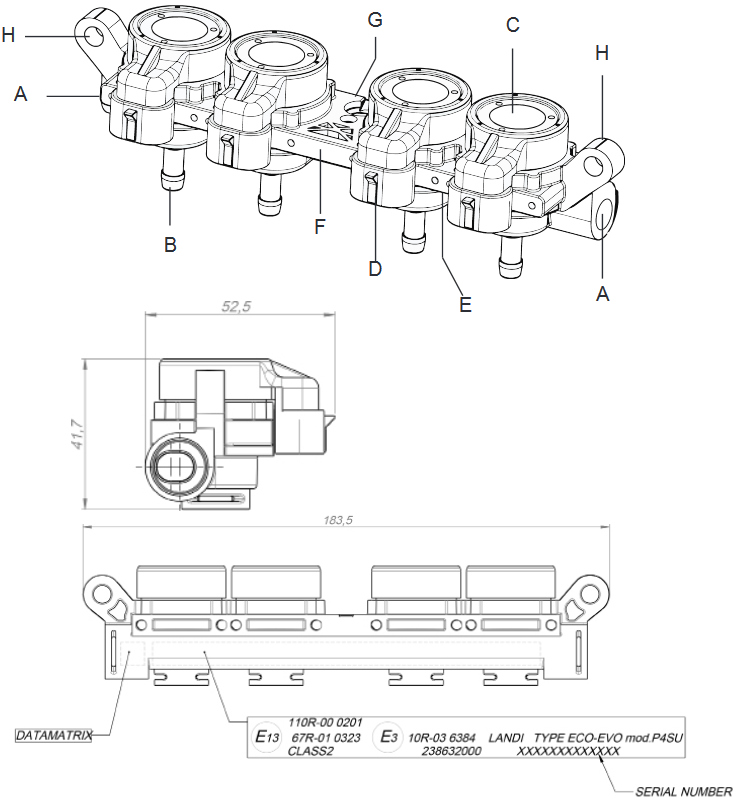

Landi Renzo ECO-EVO injector rail

The Landi Renzo ECO-EVO injector rail combines the technical characteristics of a high-end injector rail with excellent resistance to impurities in the gas, so that the use of a gas filter is not absolutely necessary.

The EVO injector rail combines the technical characteristics of a high-end injector rail with excellent resistance to impurities in the gas, so that the use of a gas filter is not absolutely necessary. The gas exiting the filter exits from inlet “A” and fills the common chamber of the injector group. With appropriate dosage, the gas exits the injectors via nozzles “B” and reaches the intake manifold and thus the engine via a specific connection. The injectors are driven by the gas control unit and connected to it via the “D” connectors.

The injectors are of one size, the different flow rate is determined by the installed nozzles. The increasing figure of numbers written on the metal nozzles and the colouring of plastic nozzles shows the large size of the injectors.

Versions

| CC / cylinder | kW / cylinder | |||

| 10 – 15 kW | 10 – 20 kW | 20 – 25 kW | over 25 kW | |

| 200 – 280 cc | 1,8 mm | 1,8 mm | 2,0 mm | 2,2 mm |

| 290 – 370 cc | 2,0 mm | 2,0 mm | 2,2 mm | 2,4 mm |

| 380 – 440 cc | 2,0 mm | 2,2 mm | 2,2 mm | 2,4 mm |

| 450 – 500 cc | 2,2 mm | 2,4 mm | 2,6 mm | |

| up to 510 cc | 2,6 mm | 2,6 mm | ||

Notations

- Gas inlet connector

- Gas outlet nozzles

- Injectors

- Injector connectors

- Injector size

- Injector case

- Homologation number

- Fixing points

Homologation

- E13 67R-010290

- E13 110R-000123

- E3 10R-046345

Application Injector injection nozzles

| Size | Plug colour |

| 1.6 mm | Red |

| 1.8 mm | Yellow |

| 2.0 mm | Green |

| 2.2 mm | Black |

| 2.4 mm | White |

| 2.6 mm | Grey |

Specifications

| Fuel type | LPG, CNG | |||||

| Type of injector | normally closed | |||||

| Gas inlet | side feed | |||||

| Working pressure | 0.5 ÷ 4.5 bar | |||||

| Test pressure | 10 bar | |||||

| Coil resistance | 1.96 ohm | |||||

| Peak current | 4.4 A | |||||

| Maintenance current | 2.0 A peak & hold | |||||

| Voltage working | 4.5/13.5 V | |||||

| Opening time | 2.45 ms | |||||

| Closing time | 1.9 ms | |||||

| Operating temperature | -20° C / +120° C -40° C / +120° C (metal model) |

|||||

Additional

Maintenance

- every 60,000 km

Endurance

- 300 million cycles

Downloads

In our download area, you will find everything you need and want to know about natural gas and liquefied petroleum gas, categorized by brand name. Click on the desired manufacturer and receive the data sheets, regulatory approvals, the latest software versions, and product information at your free disposal. If you cannot find what you are looking for, we will be happy to find the necessary data or information for you.

We look forward to hearing from you

Do you have any questions or suggestions?

Please contact us. We will be happy to help you.

Please contact us. We will be happy to help you.