Sikaflex®-221

Multifunctional adhesive and sealant with a wide adhesion spectrum

Sikaflex®-221 is a versatile one-component polyurethane adhesive and sealant for a wide range of substrates such as metals, primers and coatings (two-component systems), ceramic materials and plastics. Sikaflex®-221 is suitable for producing permanently elastic joints.

Good adhesion on a variety of substrates

Resistant to aging

can be sanded and painted over

Overview

Product advantages

- Good adhesion on a variety of substrates

- Resistant to aging

- can be sanded and painted over

- Tested to EN45545-2 R1/R7 HL3

- Non-corrosive

- Low odour

Application

Sikaflex®-221 adheres well to a variety of substrates and is suitable for elastic, permanent waterproofing. Suitable substrates are metals, primers and paints (two-component systems), ceramic materials and plastics. Observe manufacturer’s recommendations before using Sikaflex®-221 on materials at risk of stress cracking. Pre-tests must be carried out with original materials to avoid stress cracking. This product is only suitable for experienced users. To ensure adhesion and material compatibility, preliminary tests must be carried out with original materials under the relevant conditions.

Product details

Product features

| Chemical base | 1-component polyurethane | |

| Colour (CQP001-1) | White, grey, black, brown | |

| Curing mechanism | Moisture-curing | |

| Density before curing | Depending on colour | 1.3 kg/l |

| Stability | Good | |

| Application temperature | Environment | 5 to 40 °C |

| Skin formation time (CQP019-1) | 60 minutes | |

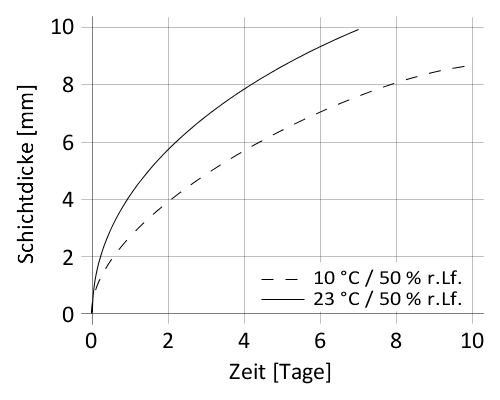

| Through-curing speed (CQP049-1) | See diagram 1 | |

| Volume change (CQP014-1) | -5 % | |

| Hardness Shore A (CQP023-1 / ISO 7619-1) | 40 | |

| Tensile strength (CQP036-1 / ISO 527) | 1.8 MPa | |

| Elongation at break (CQP036-1 / ISO 527) | 500 % | |

| Tear resistance (CQP045-1 / ISO 34) | 7 N/mm | |

| Operating temperature (CQP513-1) | -50 to 90 °C | |

| 24 Hours | 120 °C | |

| 1 Hour | 140 °C | |

| Durability (CQP016-1) | Cartridge / Bag | 12 Months |

Technical information

Sikaflex®-221 cures by reaction with air humidity. At low temperature the water content of the air is lower and the cross-linking reaction is somewhat slower, see diagram 1.

Sikaflex®-221 is generally resistant to fresh water, sea water, dilute acids and dilute alkalis; temporarily resistant to fuels, mineral oils, vegetable and animal fats and oils; not resistant to organic acids, glycol, concentrated mineral acids and alkalis or solvents.

Application

Surface pretreatment

The adhesive surfaces must be clean, dry and free from grease, oil and dust. The surface preparation depends on the specific condition of the substrate and is decisive for a durable bond. Instructions for surface pretreatment can be found in the current Sika® pretreatment table. The information contained there is based on experience and must always be verified by preliminary tests with original materials.

Processing

Sikaflex®-221 can be processed between 5 °C and 40 °C. Changes in reactivity and application properties must be taken into account. The optimum temperature for substrate and sealant is between 15 °C and 25 °C.

Apply Sikaflex®-221 with a suitable cartridge/bag gun or pumping equipment. Information on the selection and installation of a suitable pump system is available from the System Engineering department at Sika Industry.

Smoothing

Smoothing must be carried out before the sealant skin forms. For smoothing we recommend Sika® smoothing agent N. Other smoothing agents must be checked for their suitability.

Removal

Not cured Sikaflex®-221 can be removed from tools and equipment with Sika® Remover-208 or other suitable solvents. Cured material can only be removed mechanically. Hands/skin must be washed immediately with suitable cleaning cloths (e.g. Sika® Handclean) or industrial hand cleaners and water. Do not use solvents on the skin!

Overpaintability

Sikaflex®-221 can be painted over after skin formation. If the paint requires a baking process, the best result is obtained when the sealant has fully cured beforehand. Paint compatibility must be checked by preliminary tests under production conditions. As the elasticity of the varnish is lower than that of the sealant, varnish cracks may occur in the joint area.